“[…] improve the energy efficiency of hydrogen production systems”

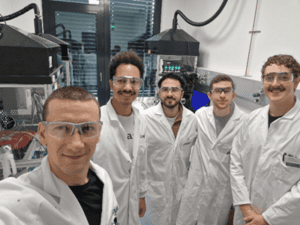

Group Picture Project KickOff, Freiburg, 18.02.2025

From left to right: Dr. Melanie Bühler (Hahn-Schickard), Dr. Waleed El Rouby (Elogen), Prof. Dr. Pierre Millet (Elogen), Dr. Serge Albacha (Elogen), Dr. Kajari Mazumder (University of Technology Chemnitz), Wissem Abderrahmane (University of Lorraine), Dr. Feina Xu (University of Lorraine), Jun. Prof. Dr. Giuseppé Sdanghi (University of Lorraine), Dr. Andreas Münchinger (Hahn-Schickard), Prof. Dr. Michael Sommer (University of Technology Chemnitz), Prof. Dr. Gaël Maranzana (University of Lorraine), Dr. Matthias Gebert (Syensqo), Dr. Matthias Breitwieser (ionysis), Dr. Severin Vierrath (ionysis).

Within the joint call “Development of the hydrogen pathway for the future energy mix”, the German Federal Ministry of Research, Technology and Space (BMFTR) and the French Ministry of Higher Education, Research and Space (MESRE) via the French National Research Agency (ANR) are funding five innovative projects that provide solutions to key challenges in the development of a hydrogen economy. One of these projects is FFWD (Fluorine-Free Water Electrolysis Development). Its portrait marks the start of a series introducing the five projects.

The research environment

1) Can you introduce yourself as a researcher?

Gaël Maranzana: I have been a professor at the University of Lorraine since 2014. I teach hydrogen technologies, renewable energies, and energy storage technologies in the Master’s program in Energy at the Faculty of Science and Technology in Nancy. My research focuses on hydrogen technologies: low-temperature water electrolysis in acidic and alkaline environments, hydrogen compression using alternatives to mechanical compressors, and proton-exchange membrane (PEM) and anion exchange membrane (AEM) fuel cells. I am particularly interested in transfer phenomena (charges, mass and heat) in these systems, from an experimental and modeling perspective. I have been working with another German team for about ten years at Bosch in Renningen.

Melanie Bühler: I have been group leader for PEM (proton exchange membrane) electrolysis in the division Electrochemical Energy Systems (EES) at Hahn-Schickard in Freiburg, Germany since 2020. I am co-lecturer for Electrochemical Energy Applications – Fuel Cells and Electrolyzers in the Master’s program at the Faculty of Engineering of the University of Freiburg. My research focuses on reducing noble metal contents in catalyst layers as well as reducing or substituting fluorine-containing substances in electrodes and membranes for green hydrogen production via PEM electrolysis.

2) In what scientific environment do you evolve?

Gaël Maranzana: My laboratory, Laboratoire Énergies & Mécanique Théorique et Appliquée (LEMTA), is a mechanical engineering laboratory. My team, called “Hydrogen electrochemical systems,” includes four permanent researchers and one engineer, two postdoctoral fellows, and 12 doctoral students.

LEMTA team involved in the project in front of the experimental bench developed to test materials at high pressure and high temperature. From right to left: Giuseppe Sdanghi (Junior Professor), Feina Xu (CNRS researcher), Wissem Abderrahmane (PhD student), Jérôme Dillet (Research engineer), Gaël Maranzana (Professor)

Melanie Bühler: The working environment at Electrochemical Energy Systems (EES) is engineering driven, interdisciplinary and located in laboratories to work on the full lifecycle development for membrane electrode assemblies starting from material synthesis, in-situ full cell testing and ex-situ end of life analysis. My group, PEM electrolysis, includes one engineer, five PhD students as well as student assistants on bachelor and master level.

HS Team from left to right: Clara Schare, Dr. Melanie Bühler, Hannes Grammel, Dr. Andreas Münchinger

TUC Team from left to right: Dr. Arun Kumar Gayen, Prof. Dr. Michael Sommer, Dr. Kajari Mazumder

Ionysis Team from left to right: Dr. Lorenz Baumgartner, Dr. Joey Disch, Juan José Castro, Alexandre Nozadze, Samuel Paparella

Presentation of the joint project

3) Can you present us your scientific project in the field of hydrogen?

Melanie Bühler: The objective of the “Fluorine-Free Water Electrolysis Development” project concerns “proton exchange membrane” water electrolysis technology. The membranes are currently made from perfluoroalkyl substances (PFAS), which are highly harmful to the environment. The initial goal is to replace them with environmentally benign hydrocarbon polymers that are fully fluorine-free. Additionally, these new polymers will be able to operate at higher temperatures and higher hydrogen pressure and thus improve the energy efficiency of hydrogen production systems.

4) Can you present us the team behind the project (pis, phd students, post docs etc)?

Gaël Maranzana: This project is a collaborative effort between academia and industry. Each academic partner (LEMTA, TU Chemnitz, Hahn-Schickard) has hired a doctoral student and assigned permanent staff to the project. The industrial partners (Elogen, ionysis GmbH, Syensqo) are investing the time of their own engineers in the project. A total of 253 persons are invested in the project.

Progress, results and applications (scientific, political, economic and social) of your project

5) After the launch of the projects in November 2024, what are the notable advances and results one year after the beginning of this adventure?

Melanie Bühler: The most notable advances in the project, apart from the fact that the teams were able to set up all the experimental tools necessary to carry out the project, concern the outstanding performance obtained thanks to a fluorine-free proton-conducting polymer developed by the associated company Syensqo. The durability of the material still needs to be proven experimentally, but the initial tests are very encouraging.

6) What are the next big steps in the development of your project and how you plan:

- By the end of the project, in two years?

Gaël Maranzana and Melanie Bühler: The next steps in the project are to convert the most promising fluorine-free polymers into a robust membrane and to optimize it to perform under extreme conditions (high temperature, high pressure). At the same time, the focus will be set on durability tests at the single cell level to underline the real-world applicability. In parallel, our self-developed polymer is dynamically tailored to circumvent weak points we reveal during screening of available polymers.

- After the project, in 5 years?

Melanie Bühler: Within a time frame of 5 years after the project, manufacturers will be able to decide whether to implement these materials on a commercial scale if they have demonstrated interesting performance characteristics, at least equal to the state of the art in fluorinated materials. For us, it will always be interesting to develop other materials that are even more efficient and less polluting.

Crossing Borders: Opportunities and Benefits

7) What are the assets and advantages of working in cooperation with Germany/France on your project?

Gaël Maranzana: Above all, we are a team that complements each other very well scientifically. We could easily have come together as part of a European project. But this Franco-German funding opportunity has acted as a catalyst, accelerating our meeting and our joint work.

8) Do you notice any differences or peculiarities in this Franco-German bilateral work?

Gaël Maranzana: Personally, I am very pleased with the involvement of our German partners, their expertise, and their enthusiasm.

Melanie Bühler: Due to the close distance between all partners in the project, the efficiency in exchange of expertise, collaboration and shared enthusiasm to develop advanced hydrogen systems in Germany and France is boosting the project.

The contribution of research, challenges and obstacles

9) In your opinion, what road does Europe still have to travel in terms of innovation and technology transfer to achieve its ambitions by 2030/2040 on hydrogen issues, and more broadly on decarbonised energy? In particular, what role does the transfer of research to industry and society play in achieving national, European and international decarbonisation objectives?

Gaël Maranzana and Melanie Bühler: Without innovation from academic and industrial players, and without transfers to industry, the CAPEX of European electrolysers will not be competitive with those produced in China in particular. This is because operating at higher temperatures and pressures will make the hydrogen produced cheaper. Efforts should be concentrated on developing safe, cheap and sustainable hydrogen production techniques, to efficiently deploy increasing amounts of surplus electricity in e.g. water electrolysis. Regarding sustainable systems, everlasting toxic polymers as PFAS-based materials should be banned and development of alternatives as e.g. hydrocarbons should be supported and clearly pushed forward.

10) According to you and your team, how does your project contribute to the construction of a decarbonised Europe in 2025?

Gaël Maranzana: As part of this project, and more generally, my team is working to improve the sustainability and efficiency of hydrogen technologies, ultimately reducing their cost and making them competitive with fossil fuels. But this only makes sense if renewable energies are developed at the same time, indeed hydrogen is only an energy carrier.

Melanie Bühler: Our research, in particular the project FFWD, contributes to the development of highly efficient and at the same time sustainable materials for green hydrogen production. However, for reaching the decarbonisation goals not only green hydrogen production, but also renewable energy sources and storage solutions need to be ramped up.

The Office for Science and Technology extends its warmest thanks to Prof. Dr. Gaël Maranzana (University of Lorraine) and Dr. Melanie Bühler (Hahn-Schickard) for their participation, and without whom this portrait would not have been possible.

Réalisation du portrait : Loïs Vaugeois

Mise à jour : 8 janvier 2026